- 73120 NC Horizontal Axis Round Table Surface Grinding Machin

- Editor:xghlDate:2019-01-09 11:26 click:

- 產品詳情

- 產品參數

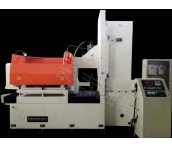

NC Horizontal Axis Round Table Surface Grinder 73120

NC Horizontal Axis Round Table Surface Grinder Skm73120

Principle and structure of the equipment:

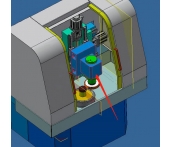

SSKMG73120 adopts the form of grinding head reciprocating motion on the trailer board and vertical motion on the column guide rail. The equipment and electrical appliances are imported, the guide rail is Rexroth, and the worktable is designed with a new design, which improves the stability and accuracy of the equipment. Bed, column and other castings are all treated with secondary tempering stress relief, which has good material quality and high strength and ensures the stability of the equipment.

Advantages:

Independent research and development of grinder feed CNC control system, parameter setting is simple and easy. After setting the size, the tool alignment, automatic resolution, automatic grinding, automatic compensation and automatic grinding quantity are automatically detected. The worktable is equipped with an automatic magnetizing and demagnetizing device, which has the functions of adjustable magnetic force and demagnetizing protection. The castings are rigid, fast, accurate and easy to operate.

Purpose:

It is suitable for the grinding of circular table surface. This machine mainly grinds circular end surface and plane workpiece in the range of diameter 1200. (customizable as required)

Applicable industries:

Saw blade factory, automobile parts factory, bearing factory, engine factory, tool factory, friction disc factory, piston factory, ceramic seal factory and general machinery factory's product workshop and tool workshop, grinding and processing precision parts;

Characteristic:

1. Strong adaptability of processed products; 2. High processing accuracy, the gap of workpiece thickness remains within 0.003 mm, and the surface roughness after processing can reach Ra 0.4 um. 3. Processing products do not deform and have good uniformity in size; 4. Operators have low labor intensity and one person controls multiple machines to reduce labor costs; 5. High production efficiency and good economic benefits; 6. Grinding machine maintenance is simple; 7. It is easy to modernize production management.

- next: 73220 NC Horizontal Axis Round Table Surface Grinding Machin

- pre: end...